The next time you're on a Delta Air Lines flight, you can breathe a little easier knowing that a UAB engineering graduate works for the carrier. August Oo joined the company at its Atlanta headquarters as an aircraft engineer in 2006, 14 years after earning his bachelor’s degree in mechanical engineering. Since then, he has held a variety of project management roles—all focused on solving problems for one of the world’s largest airlines.

Take, for instance, the time when Delta began planning to transport pharmaceuticals across the country in its cargo holds. Oo’s task was to figure out how to do that safely.

“Pharmaceuticals are perishable, high-value items,” Oo says. “To keep them cool, we need to put boatloads of dry ice on them”—sometimes up to 1,000 pounds. But dry ice is made of carbon dioxide (CO2), which has a high sublimation rate, meaning it can transform directly from a solid to a gas. Too much CO2 in the air—from sublimation combined with our own exhalations—could be dangerous for passengers. “We are safe if the CO2 level is below 2 percent of the air,” Oo says.

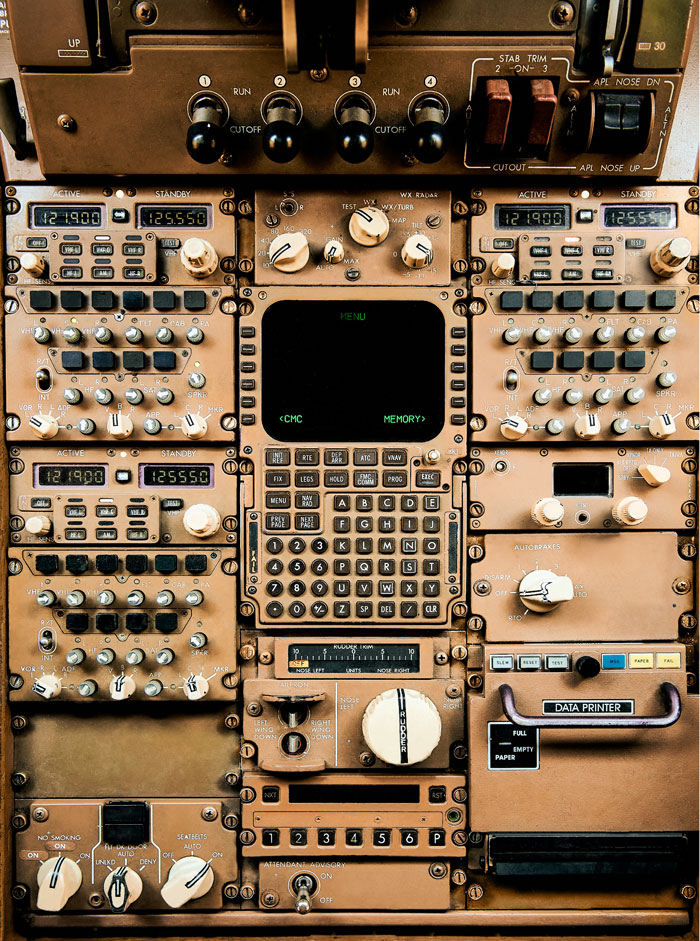

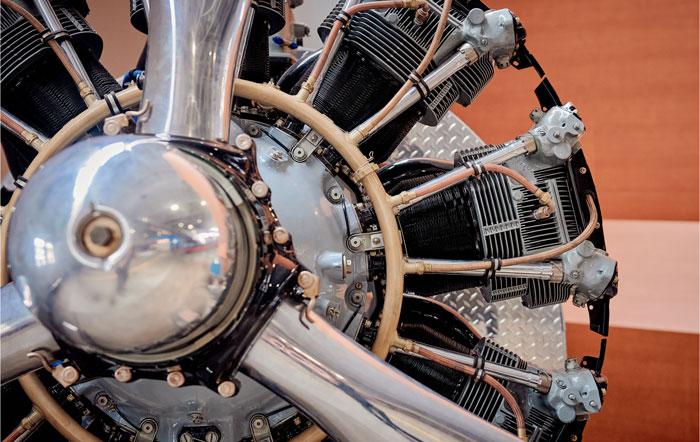

August Oo (at top and above) shares his love for aerospace during a visit to the Delta Flight Museum in Atlanta (below).

August Oo (at top and above) shares his love for aerospace during a visit to the Delta Flight Museum in Atlanta (below).Coming up with a solution took a lot of critical thinking—a skill that Oo recommends all engineering students learn. He spent months working on the issue, gauging every possible CO2 emission rate. “I put CO2 detectors all over an aircraft and then figured how much an average 180-pound person would emit,” Oo says. His calculations helped the airline determine how much dry ice it could use aboard a flight.

In the end, the CO2 numbers varied, but they stayed below 1.25 percent. “We never got close to an alarming rate,” Oo says. Both passengers and pharmaceuticals could fly safely and securely.

Oo credits much of his success at Delta to his engineering education. A native of Burma, he moved to Alabama with an aunt as the Asian nation experienced political unrest. He entered UAB after completing high school in Birmingham. “At UAB, I learned how to solve a problem,” Oo says, noting that the late Martin Crawford, Ph.D., professor of mechanical engineering, was a key influence on him. In fact, Oo first experimented with using CO2 as a coolant as part of a senior project in Crawford’s class. “I never would have thought that 11 years later I would be studying CO2 again, this time to keep it at a safe level on an aircraft,” Oo says.

Now Oo’s problem-solving experience has helped his career take off once more. He recently was promoted to customer service manager in Delta’s Maintenance Repair Overhaul department. In this role, his clients are other carriers.

Because Delta has a large fleet of Airbus A330 planes that it has operated for a long time, its maintenance staff have become experts at fixing problems that may arise, Oo explains. So when regional airlines with smaller fleets and less experience begin using the A330, they often outsource the maintenance to Delta.

Oo says he is quickly growing into his new job, traveling often to support his customers and, ultimately, their passengers. “We know how to take care of these planes and keep them flying,” he says.