Diamonds may sparkle on the hand, but they really shine under pressure. Diamond’s durability—it is the hardest naturally occurring mineral—and its superior mechanical and thermal properties, make it ideal for tough industrial jobs, such as heavy grinding and fine cutting.

That is why far more diamonds are created synthetically each year than mined from the ground, although the creation process is roughly the same: applying high temperatures and high pressures to graphite.

UAB’s Yogesh Vohra, Ph.D., takes a different approach. Vohra, a University Scholar, professor in the Department of Physics, and associate dean in the College of Arts and Sciences, “grows” diamonds by mixing methane with hydrogen in a process called microwave plasma chemical vapor deposition. These vapor-deposited coatings can then be applied to a variety of products in a way that previously was not technically feasible or economically viable.

It’s an ideal business opportunity, and with the help of a $600,000 Partnerships for Innovation (PFI) grant from the National Science Foundation, UAB and the Birmingham Business Alliance (BBA) are working to turn this intellectual property into a high-tech job creation engine. The grant “will allow us to make the transition from laboratory-based prototypes to designs that can be manufactured and mass-produced,” says Vohra. “I think there will be a lot of local economic impact from this grant.”

The UAB-developed technology could help existing Birmingham businesses expand and spark the creation of new start-up companies as well, explains Steven Ceulemans, vice president of innovation and technology for the BBA. “There are existing companies making products that could be enhanced by coating them with diamonds, giving them access to new markets and making them more competitive in selling their products nationally and globally,” Ceulemans says. “Other companies could relocate to the Birmingham area, and ultimately there might be some spin-off opportunities in completely novel applications that can emerge from this research as well.”

Ceulemans says this partnership is exactly the type of collaboration envisioned in the Blueprint Birmingham long-term economic plan adopted by the BBA in 2010 for the seven-county Birmingham region. “We’re working on ways to grow the knowledge economy in Birmingham, and UAB is a very big part of that, especially when it comes to research-driven innovation,” Ceulemans says.

UAB and the BBA already have developed a partnership with three companies—Almax easyLab, Onyx Optics, and Birmingham-based Vista Engineering—to develop three types of diamond products:

Lasers

UAB researchers have applied their nanostructured diamond coatings to glass. Since diamond is an excellent conductor of heat—five times greater than copper—these coatings can help efficiently cool devices that generate heat during operation, such as lasers. Vohra says Onyx Optics is exploring how these diamond-coated crystals can be used in their adhesive-free bonding products for potential applications in high-powered lasers. One possible use: weapons-grade solid-state lasers being developed by the military. Knee and Hip Joints

Knee and Hip Joints

UAB has patented a process for depositing ultra-hard nanostructured diamond coatings on metals to make them more resistant to mechanical wear. These coatings are perfect for artificial joints (pictured at right); they are two to three times more wear resistant than standard surfaces in hip and knee prostheses, Vohra says. Vista Engineering is providing technical expertise in diamond coatings of titanium alloys.

With the PFI grant, Vohra’s group is now testing the coatings in a UAB knee simulator to “establish their longevity in clinical settings—and their competitive advantage over the standard knee prosthesis on the market,” Vohra says. The BBA, along with the UAB Institute for Innovation and Entrepreneurship, is providing a market analysis of diamond-coated knee prostheses and the potential for market penetration.

Sensors

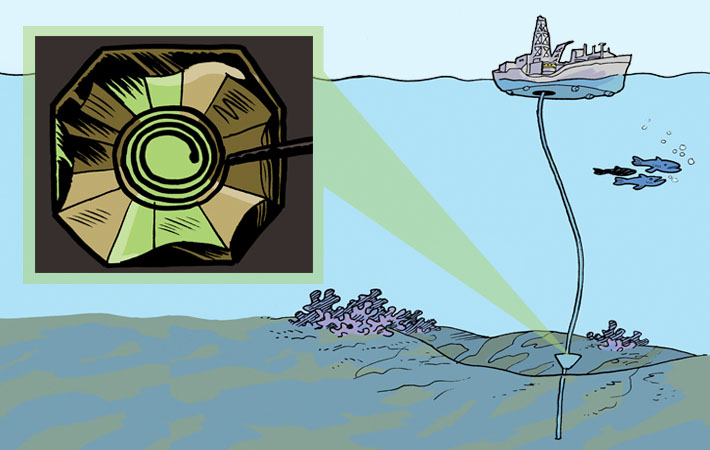

UAB researchers, in collaboration with the Lawrence Livermore National Laboratory in California, have used chemical vapor deposition to create diamond-based sensors that can be used for electrical, magnetic, and stress sensing in extreme conditions. These sensors work in applications where conventional sensors would fail because of issues involving temperature, stress, chemicals, or high radiation levels. Almax easyLab is providing diamond polishing expertise as well as developing new markets for these sensors.

The PFI grant allows UAB researchers to explore different orientations of diamond crystals and diamond growth chemistry in order to devise a production-ready process “that can incorporate multiple sensors in one diamond,” Vohra says. “The 3-D integration of sensors will result in a diamond sensor product that will be multifunctional, which will be highly attractive for commercialization.”

The first commercial applications will be in designer diamond anvils, which are used in experiments requiring high pressures and high temperatures, Vohra says. Future users could include the oil and natural gas industry. Diamond-based sensors that can withstand extreme pressures and temperatures have many commercial applications. The sensors, installed inside a drilling bore, could transmit data about the stresses encountered in deep-sea drilling for oil and natural gas, for example.

Diamond-based sensors that can withstand extreme pressures and temperatures have many commercial applications. The sensors, installed inside a drilling bore, could transmit data about the stresses encountered in deep-sea drilling for oil and natural gas, for example.

Get Involved

• Learn more about UAB research in physics.

• Discover how UAB is boosting Birmingham's bottom line through economic development.

• Give something and change everything for researchers in the UAB Department of Physics.