Need more information? Contact us

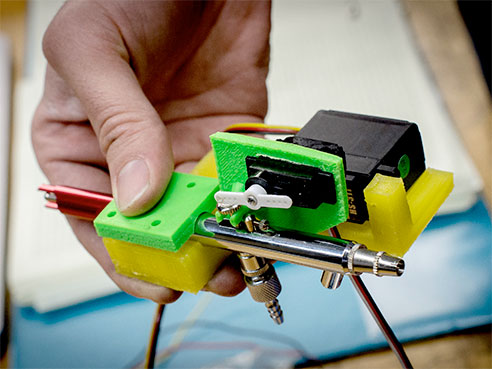

Close-up section of R2 Paintbot, the world's first automated mural painting system, which will be one of many innovative projects on display at Senior Design Media Day.A variety of projects that provide innovative and creative solutions to industrial challenges will be displayed in UAB’s Business-Engineering Complex during Senior Design Day on Wednesday, April 15. The projects were designed and built by interdisciplinary teams from the departments of Mechanical Engineering and Materials Science and Engineering during the fall and spring semesters.

Close-up section of R2 Paintbot, the world's first automated mural painting system, which will be one of many innovative projects on display at Senior Design Media Day.A variety of projects that provide innovative and creative solutions to industrial challenges will be displayed in UAB’s Business-Engineering Complex during Senior Design Day on Wednesday, April 15. The projects were designed and built by interdisciplinary teams from the departments of Mechanical Engineering and Materials Science and Engineering during the fall and spring semesters.

Many of the teams worked with local companies to devise solutions to industry problems.

“Once again, our students have done an excellent job during the past two semesters designing and fabricating systems and devices,” said Hessam Taherian, Ph.D., an assistant professor in the Department of Mechanical Engineering. “Many of these projects attempt to solve engineering problems that industries face, while others prove the viability of innovative concepts.”

Projects will be on display in the BEC Lobby, and students will be available for questions or demonstrations from 11 a.m. until 12:30 p.m.

This year’s exhibition includes these seven projects:

Altec Body-Leak Test

Altec is one of the world’s leading providers of custom utility trucks. Founded in Birmingham in 1929, Altec has developed a strong bond with the School of Engineering during the past decades. Students this year were challenged to help Altec develop leak-proof bodies in extreme weather conditions. This led to the creation of the Altec Hurricane Leak Test Station, in which water hits every inch of even the largest bodies at a minimum velocity of 80 miles per hour. This new test established a new standard in custom utility bodies.

Altec Body Lift Mechanism

The Altec Body Lift Mechanism Project helped resolve a truck-body-loading inefficiency. Altec’s process for loading newly made truck bodies involved three forklifts and careful maneuvering of thousands of pounds of metal, which took much time and careful planning. The senior design team worked with UAB and Altec mentors to devise a solution — an above-ground loading dock that makes loading simpler and faster because it requires only one forklift. Altec has approved the design, and the company plans to invest $90,000 to $150,000 to build the project.

Filament Winder

The purpose of this project is to design and construct a filament-winding machine for a local company. The machine will be used to wind continuous fiber-reinforced thermoplastic tape around thin-walled pipe. This potentially will increase the pipe’s strength and corrosion resistance while reducing its cost and weight. The goal is to produce a functioning filament-winding machine, wind a pipe 4 feet long and 8 inches in diameter, and test the strength of the pipe to determine the amount of strength added by filament-winding.

Car-Cooling System

The Renewable Car-Cooling System is a proof-of-concept research project sponsored by Southern Company that integrates a type of smart-film technology and active ventilation system to maintain the interior temperature of the car at ambient outdoor temperature using a completely independent power system. In warm, sunny conditions, the temperature in a car cabin can exceed 120 degrees Fahrenheit; thus, a commercial solution could reduce power consumption when cooling the car cabin. The product could be designed as an add-on to existing vehicles or a feature for newer car models, and it could be marketed as a luxury item for traditional combustion-engine vehicles or as a range-extender for electric vehicles.

Electric Car

The goal for this project is to improve and optimize the performance of an electric car built by this past year’s senior design team. This team has made upgrades to the power supply and steering system and constructed a new body for the car. The team has entered the newly modified car in the Barber Motorsports Park Electrathon competition, in which the car will attempt to travel the farthest distance with a limited amount of time and power.

R2 Paint System

The R2 PaintBot is an automated mechanical system that can print large images onto walls and most other vertical surfaces using paint. The paint is applied to the surface in four colors using a manifold of airbrushes with several custom attachments and 3D-printed paint reservoirs. It is supported by a 12-foot-tall structure and uses a motor-driven, triangulated hoisting system to move the airbrush manifold. The project was inspired by the Magic City Mural Collective’s effort to include a mural in every one of Birmingham’s neighborhoods, and it is intended to be used to paint interesting works of art designed by local artists around the city.

Unmanned Aerial Vehicle (UAV)

The development of unmanned aerial vehicles has grown exponentially since the advent of high-powered microcontrollers. Most UAVs find application from opposite ends of the spectrum: high-powered military use or recreational use. Commercialization is expected in due time, and capable UAVs to fit the commercial atmosphere will be in demand. This project focuses on tackling the qualities a business would find desirable in a product: capable, robust, customizable and cost-efficient. The basic capabilities include a sound design optimized for maximizing flight time while maintaining proper payload, speed and controllability. A great focus has been placed on robustness and the ability of the UAV to withstand the elements. The design optimizes protection of the propulsion system and enhances propulsion by using a customized shroud design. An open-source controller enables the UAV to be customized with peripheral devices and access to source code for most desirable modifications. Telemetry allows for real-time video feed and data-logging while the vehicle is in operation.