Rapid Prototyping Fuels Space Science

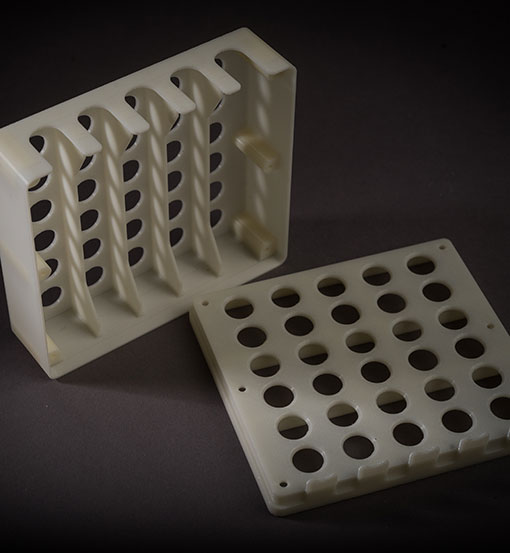

UAB mechanical engineer Brian Cooper went through two 3D-printed iterations of this container for protein crystal growth experiments in space. The final version was shaped in aluminum, but the prototypes found new life as training devices for astronaut scientists.

UAB mechanical engineer Brian Cooper went through two 3D-printed iterations of this container for protein crystal growth experiments in space. The final version was shaped in aluminum, but the prototypes found new life as training devices for astronaut scientists.

David Cooper hasn’t visited space himself, but he has been there by proxy. As a mechanical engineer in UAB’s Center for Biophysical Sciences and Engineering (CBSE), Cooper has worked on several NASA contracts, including the UAB-designed GLACIER and Polar freezers now orbiting Earth aboard the International Space Station.

A recent assignment charged him with designing a container for protein crystal growth experiments on the space station. “You can do a lot of math regarding making things fit, but you’ll never know how it will work and what it will feel like until you actually make the object,” Cooper says.

Cooper usually sends his designs as computer files to a manufacturer that shapes the device in aluminum, a process that takes several weeks, with a per-unit cost of $1,000. But he recently discovered the 3D Print Lab. For a mere $130, Sloan’s group printed a working model of the test tube tray (above). “That first iteration was a little loose,” Cooper says. “So I made a slight adjustment, and it worked better.”

The final version was still printed in aluminum. The material used in UAB’s 3D printers is not yet cleared for spaceflight, Cooper says, “but I think we’ll get to that point soon.” Still, Cooper’s test models haven’t gone to waste. They, and a few duplicates, are now in Houston, where they are being used to train the astronauts who will be doing the experiments in orbit.

“It’s very handy to have this service right down the road from us,” Cooper says. “I can just send them the file, then walk over and pick up the prototype the next day.”