Refractory Ceramics

Our research in refractory ceramics encompasses developing new non-toxic materials for furnace linings for steel and other industrial manufacturing sectors and delving into the fundamental structure-property relationship. The primary focus of our research is to increase the service life of the furnace linings which contributes to overall energy savings and decarburization of the energy intensive manufacturing sectors. The UAB team collaborates with the Oak Ridge National Laboratory and industries. Our core expertise includes prediction of thermochemical stability and experimental validation, ceramic processing, and mapping the corrosion mechanisms, and finally converting the basic understanding to innovate corrosion resistant new materials. Another focus of our research to search for refractory ceramics suitable for alternate fuels to meet the decarburization goal of the manufacturing sectors.

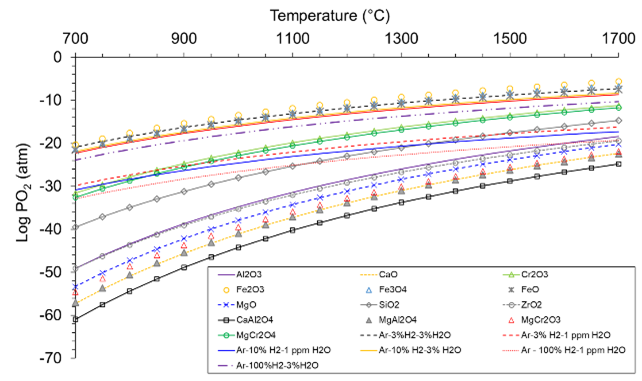

Dissociation pressure (PO2) of refractory oxides

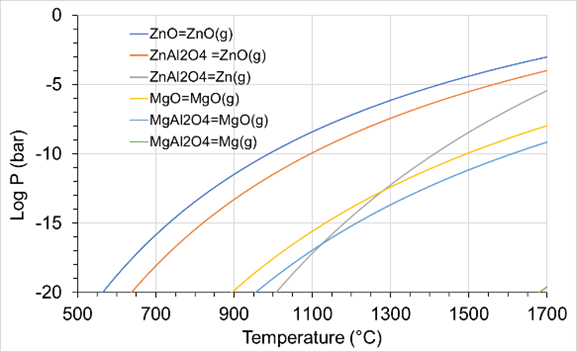

Dissociation pressure (PO2) of refractory oxides  Vapor pressure vs. temperature of oxides

Vapor pressure vs. temperature of oxides

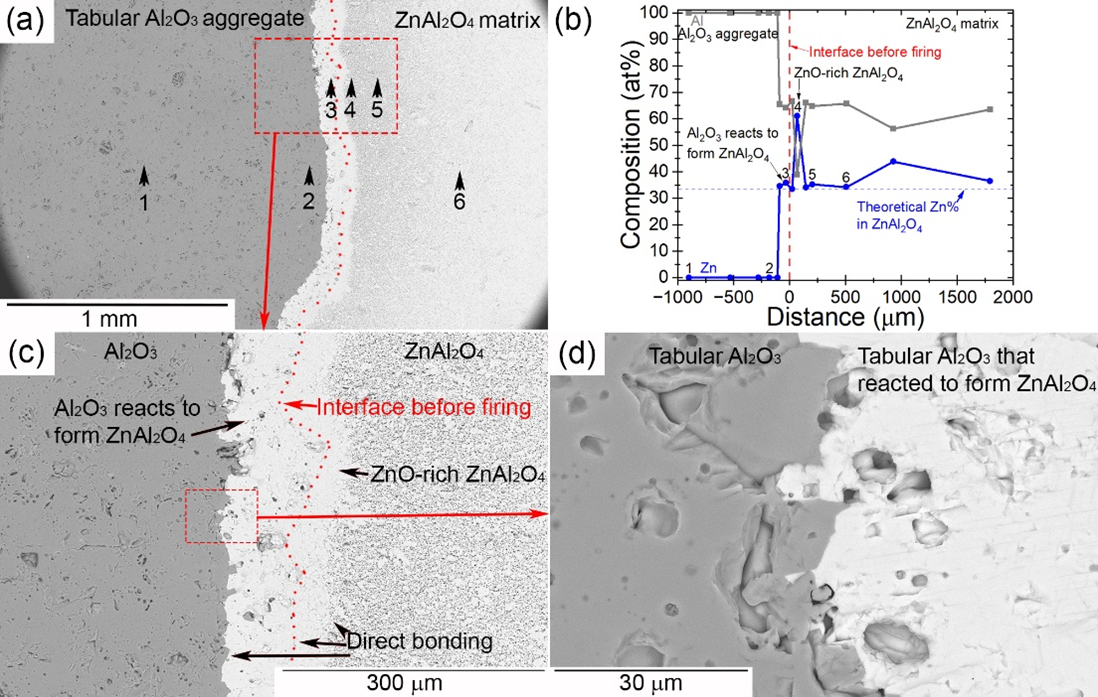

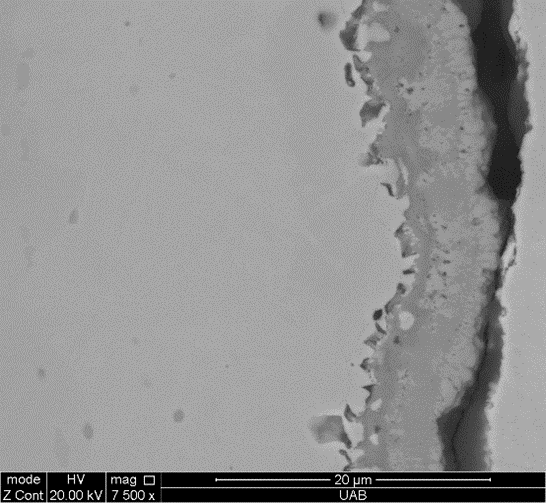

Interfacial compatibility of newly developed gahnite refractory with industrial grade tabular alumina

Interfacial compatibility of newly developed gahnite refractory with industrial grade tabular alumina

Protective Coatings

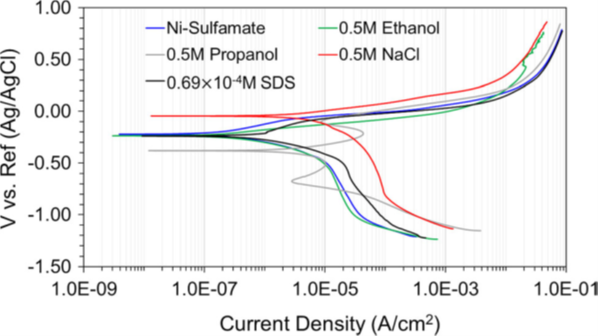

Corrosion of materials, a naturally occurring phenomenon, is a major challenge for industries, aging infrastructure including naval assets, historical structures, and artwork. Our research focuses on corrosion resistant metallic and ceramic protective coatings for aqueous corrosion as well as high temperature corrosion for clean energy sectors such as solid oxide fuel/electrolysis cells, steam and gas turbines, and nuclear power plants. We deploy chemical and electrochemical routes for well-adherent, virtually flawless coating deposition on metallic substrates and evaluate its corrosion resistance.

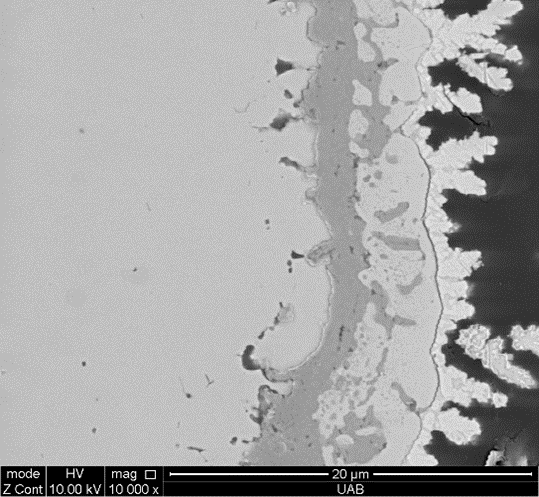

The cross-sectional microstructure of the nickel coated AISI 430 alloy exposed in (a) humidified air, and (b) hydrogen atmosphere at 800°C for 100 h.

The cross-sectional microstructure of the nickel coated AISI 430 alloy exposed in (a) humidified air, and (b) hydrogen atmosphere at 800°C for 100 h.

The high-temperature corrosion resistance in gaseous environment of nickel-coated alloy is suited for protective coatings for high temperature applications. The research in this area can be expanded for developing various coatings for diverse applications including corrosion resistance in molten salt environments.

In addition to the above currently active research area, the PI has extensive research expertise in sealing glass and glass materials as well as functional materials for high temperature solid oxide electrochemical systems.