-

Polymer-Derived Ceramics

Polymer-Derived Ceramics

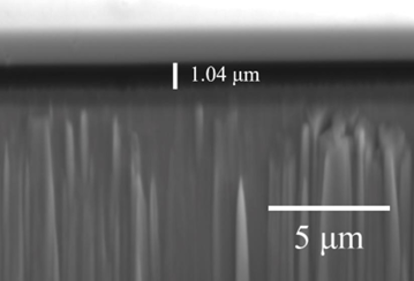

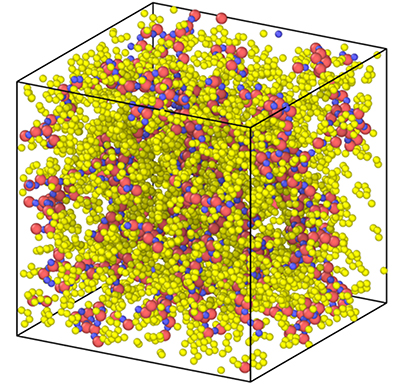

Polymer-derived ceramics have a wide array of promising properties such as high temperature stability, semiconductivity, and controllable microstructure and crystallization that can be finely tuned by altering the chemical composition of the starting polymer and the processing temperature and atmosphere. Current research is focusing on using silicon oxycarbide (SiOC) in environmentally stable and electrically conductive coatings, producing micro- and mesoporous SiOC ceramics with high specific surface areas, and introducing metal organics into the preceramic polymers to produce SiOC with magnetic and electrically conductive properties. We are also studying novel composite synthesis and preparing for flight experiments to the International Space Station.

-

Nuclear Materials

Nuclear Materials

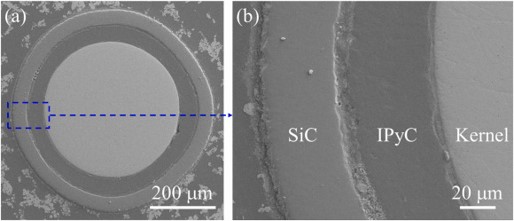

Nuclear fuel design for improved irradiation resistance, easy processibility, stress tolerance, and thermal management, lab testing and ion irradiation to understand the fuel particle and bulk evolution behaviors under the simulated harsh nuclear environments, and comprehensive characterization of atomic to macroscopic structures. This will enable novel nuclear fuel encapsulants, improve fuel damage tolerance, understand self-stabilizing behavior under irradiation, and predict this new material system behaviors for nuclear fuel advancement.

-

New Coatings for Stainless Steel

New Coatings for Stainless Steel

Our interest is to develop novel coatings for nuclear fuel waste canisters in order to address nuclear waste container corrosion and failure problems, identify new and effective mitigation strategies, and safeguard nuclear waste storage, transport, and disposal, in both terrestrial and marine environments. Specifically, we develop effective corrosion-resistant polymer-derived ceramic coatings on 304/304L/304H canisters for improved resistance to pitting in chemically aggressive, chronically stressed, and highly corrosive nuclear environments; evaluate coating structural changes under different nuclear waste storage conditions and test their corrosion responses under aggressive and long-term brine conditions; and advance fundamental understanding of the coating failure mechanisms under combined stress and corrosion conditions as well as identify coating failure repair strategies, especially when exposed to pitting and stress corrosion cracking environments.

Contact:

For more information, please contact Kathy Lu at