Refractory Ceramics

Our research in refractory ceramics encompasses developing new non-toxic materials for furnace linings for steel and other industrial manufacturing sectors and delving into the fundamental structure-property relationship. The primary focus of our research is to increase the service life of the furnace linings which contributes to overall energy savings and decarburization of the energy intensive manufacturing sectors. The UAB team collaborates with the Oak Ridge National Laboratory and industries. Our core expertise includes prediction of thermochemical stability and experimental validation, ceramic processing, and mapping the corrosion mechanisms, and finally converting the basic understanding to innovate corrosion resistant new materials. Another focus of our research to search for refractory ceramics suitable for alternate fuels to meet the decarburization goal of the manufacturing sectors.

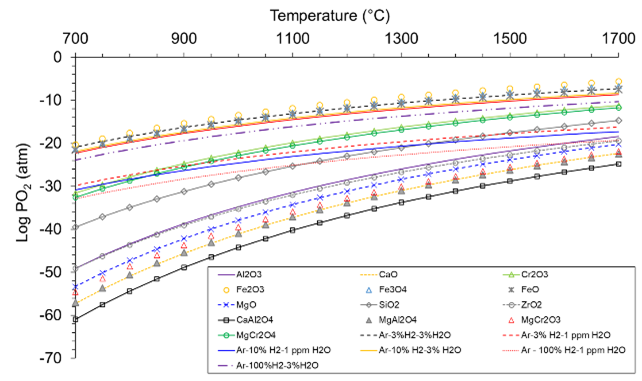

Dissociation pressure (PO2) of refractory oxides

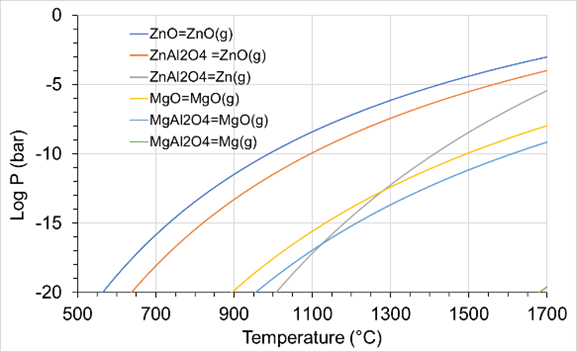

Dissociation pressure (PO2) of refractory oxides  Vapor pressure vs. temperature of oxides

Vapor pressure vs. temperature of oxides

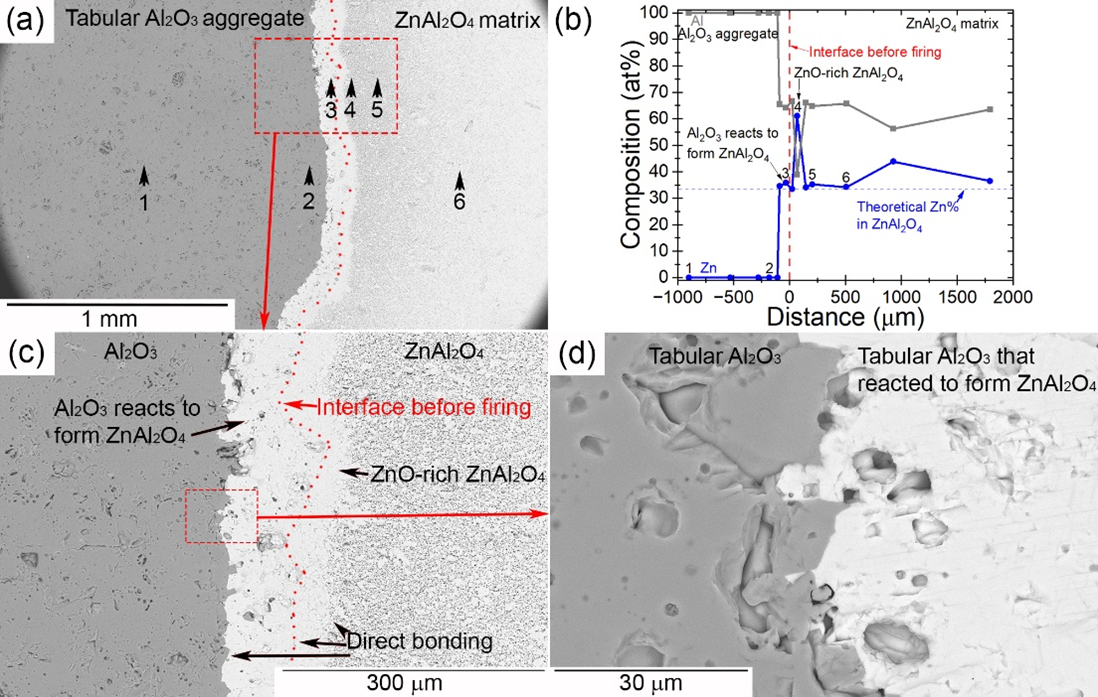

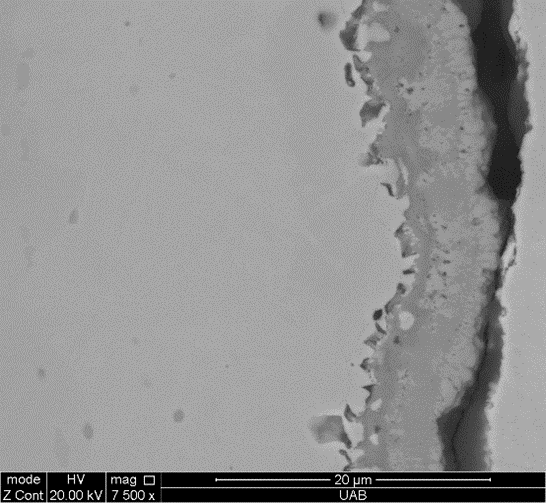

Interfacial compatibility of newly developed gahnite refractory with industrial grade tabular alumina

Interfacial compatibility of newly developed gahnite refractory with industrial grade tabular alumina

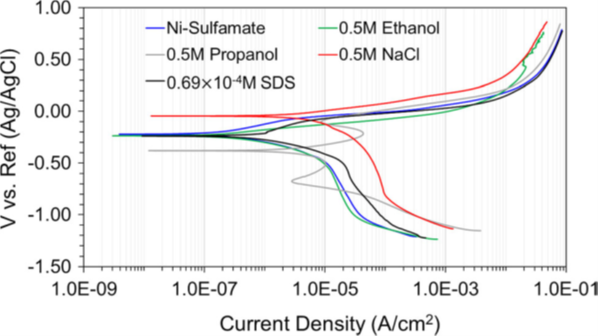

Protective Coatings

Corrosion of materials, a naturally occurring phenomenon, is a major challenge for industries, aging infrastructure including naval assets, historical structures, and artwork. Our research focuses on corrosion resistant metallic and ceramic protective coatings for aqueous corrosion as well as high temperature corrosion for clean energy sectors such as solid oxide fuel/electrolysis cells, steam and gas turbines, and nuclear power plants. We deploy chemical and electrochemical routes for well-adherent, virtually flawless coating deposition on metallic substrates and evaluate its corrosion resistance.

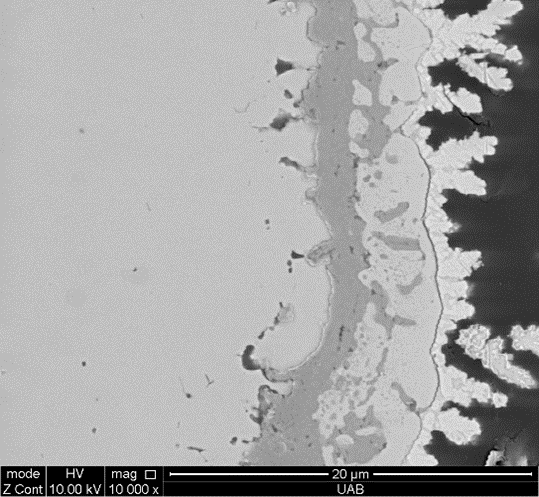

The cross-sectional microstructure of the nickel coated AISI 430 alloy exposed in (a) humidified air, and (b) hydrogen atmosphere at 800°C for 100 h.

The cross-sectional microstructure of the nickel coated AISI 430 alloy exposed in (a) humidified air, and (b) hydrogen atmosphere at 800°C for 100 h.

The high-temperature corrosion resistance in gaseous environment of nickel-coated alloy is suited for protective coatings for high temperature applications. The research in this area can be expanded for developing various coatings for diverse applications including corrosion resistance in molten salt environments.

In addition to the above currently active research area, the PI has extensive research expertise in sealing glass and glass materials as well as functional materials for high temperature solid oxide electrochemical systems.

Separation of carbon dioxide from the products of combustion of fossil fuels in large industrial facilites such as electric power plants and injection of the carbon dioxide for permanent storage in suitable geologic formations underground is a practical approach to slowing the accumulation of carbon dioxide in Earth's atmosphere and its contribution to climate change. This is best seen as an interim measure, needed to slow the pace of climate change during the period required for transition to renewable energy and development of the technology and infrastructure for beneficial utilization of carbon dioxide. In addition to its separation from combustion products, capture of carbon dioxide from the atmosphere is also an important component of the interim plan (Kolbert, 2017).

One of the essential features of a geologic formation suitable for carbon dioxide storage is the presence of impermeable seal layers or caprocks above the zone in which the carbon dioxide is stored, to prevent leakage and upward migration of carbon dioxide toward the surface. Leakage could result in contamination of underground sources of drinking water, which are at shallower depths than the geologic reservoirs under consideration for storage of CO2.

The UAB Caprock Integrity Laboratory was established in 2010 with funding through a Contribution Agreement with Southern Company Services. Since its startup, the laboratory and its investigators have participated in successful partnerships on projects with Advanced Resources International, Alabama Power Company, Denbury Resources, Montana State University, the National Energy Technology Laboratory, Oklahoma State University, Southern Company, and the Southern States Energy Board. Properties of both caprocks and reservoir rocks have been the subjects of research in connection with unconventional gas production (Puckette et al., 2016), seal formation by biomineralization (Phillips, 2013), and commercial-scale CO2 storage (Koperna et al., 2017).

A focus of research projects in the Caprock Integrity Laboratory has been on the "minimum capillary displacement pressure," or "breakthrough pressure," of gas through rocks saturated with brine (Hildenbrand et al., 2002, 2004). In the course of those investigations, it was discovered that the effective permeability of a rock to gas could be determined over the entire range from zero, just prior to breakthrough from a fully brine-saturated rock, up to a maximum effective permeability at the minimum brine saturation, with determination of the functional relationship between effective permeability and gas pressure. Knowledge of this relationship provides a useful tool with which to anticipate the evolution of the effective permeability of a saline formation with progress of CO2 injection and the conditions required to prevent seepage of CO2 through caprocks.

A focus of research projects in the Caprock Integrity Laboratory has been on the "minimum capillary displacement pressure," or "breakthrough pressure," of gas through rocks saturated with brine (Hildenbrand et al., 2002, 2004). In the course of those investigations, it was discovered that the effective permeability of a rock to gas could be determined over the entire range from zero, just prior to breakthrough from a fully brine-saturated rock, up to a maximum effective permeability at the minimum brine saturation, with determination of the functional relationship between effective permeability and gas pressure. Knowledge of this relationship provides a useful tool with which to anticipate the evolution of the effective permeability of a saline formation with progress of CO2 injection and the conditions required to prevent seepage of CO2 through caprocks.

Demonstration of the sealing ability of caprocks is not only a key to insuring the long-term retention of injected CO2 but a requirement for regulatory permitting and public acceptance of geologic sequestration. Assuring satisfactory injectivity of a storage reservoir from start to finish is essential to guaranteeing the economic viability and success of a sequestration project.

The following properties of cores from the injection and confining zones of potential geologic storage targets are measured routinely in the Caprock Integrity Laboratory:

- Porosity and grain density

- Permeability to nitrogen, helium, or carbon dioxide as functions of confining pressure and pore pressure

- Minimum capillary displacement pressure (breakthrough pressure) and effective permeability to nitrogen or helium versus pressure, for rock initially saturated with brine.

- Changes in porosity and permeability on exposure to supercritical carbon dioxide

Quantitative knowledge of these rock properties and behaviors increases the reliability with which caprock integrity and reservoir injectivity can be predicted, to reassure the public, provide technical data for permitting, and reliable analysis to the operator of a storage project that carbon dioxide storage will be safe, secure, and cost effective.

Caprock Integrity Laboratory

Location: BEC 167A

Laboratory Director: Dr. Peter Walsh

These facilities are used for research by students in the undergraduate Honors Program. The Mechanical Engineering Department established and equipped (with support from the U.S. Department of Energy/National Energy Technology Laboratory, Alabama Power Company, and Southern Company) a laboratory for evaluation of the properties of seal layers, or caprocks, that will prevent upward migration of carbon dioxide from geologic formations in which it has been sequestered, to underground sources of drinking water and the atmosphere.

A cylindrical plug of caprock is enclosed in a triaxial flow cell equipped with sealed cavities on both ends (Hildenbrand et al., 2002, 2004). The sample is first saturated with water or brine. A high pressure of gas, above the anticipated breakthrough pressure, is then applied to one end of the plug, with the other end initially at atmospheric pressure. After a time lag that can be many days, when the gas breaks through, the difference in pressure between the upstream and downstream cavities asymptotically approaches a residual pressure difference characteristic of the rock, corresponding to the capillary pressure in the conducting pore having the largest effective diameter. This is the "minimum capillary displacement pressure," above which capillary flow will occur through the rock, given sufficient time.

The measurement is an alternative to the traditional method of continuously increasing the pressure of gas on one face of a brine-saturated plug until breakthrough is observed. The traditional method tends to overestimate the breakthrough pressure because there can be a time lag of days or weeks before gas appears on the downstream side of a plug, even at upstream pressures well above the pressure ultimately identified as the breakthrough pressure. Experiments are conducted using both nitrogen and carbon dioxide gases, with brine characteristic of the reservoir under study. The use of nitrogen permits measurements to be made in the absence of changes in permeability caused by dissolution of the rock by the acidic aqueous solution of CO2, or precipitation of dissolved solids from the brine.

References

- Hildenbrand, A., S. Schlömer, and B. M. Krooss, "Gas breakthrough experiments on fine-grained sedimentary rocks," Geofluids, 2002, 2, 3-23.

- Hildenbrand, A., S. Schlömer, B. M. Krooss, and R. Littke, "Gas breakthrough experiments on pelitic rocks: comparative study with N2, CO2 and CH4," Geofluids, 2004, 4, 61-80.

- Kolbert, E., "Can carbon-dioxide removal save the world?," The New Yorker, November 20, 2017.

- Koperna, G., J. Pashin, and P. Walsh, "Commercial Scale CO2 Injection and Optimization of Storage Capacity in the Southeastern United States," Final Scientific/Technical Report, DOE Cooperative Agreement DE-FE00110554, Submitted by Advanced Resources International, Inc., Oklahoma State University, and University of Alabama at Birmingham, October 27, 2017.

- Phillips, A. J., "Biofilm-Induced Calcium Carbonate Precipitation: Application in the Subsurface, Ph.D. Dissertation, Montana State University, Bozeman, October 2013.

- Puckette, J., J. Pashin, P. Clark, S. Mohamed, J. White, D. Kopaska-Merkel, G. Jin, J. Dawson, D. Hills, P. Walsh, and M. Hannon, "Petrophysics and Tight Rock Characterization for the Application of Improved Stimulation and Production Technology in Shale," Final Report DE-AC26-07NT42677, Prepared for the Research Partnership to Secure Energy for America under Contract 11162-23 by Oklahoma State University, Geological Survey of Alabama, and University of Alabama at Birmingham, June 26, 2016.

Contact

For more information, please reach out to Peter Walsh at

Mechanical Systems Lab

The Mechanical Systems Laboratory is an undergraduate lab facility to support the ME 461 course and undergraduate research work. The central idea of this lab facility is to demonstrate and learn main mechanical engineering principles in action. Students gain learning experience through conducting experimental work, observing, measuring and analyzing experimental results that prove main engineering principles.

Location: BEC 164

Available Experimental Apparatuses

-

Research Interests

Robin Foley is part of the Materials Engineering metals research group. She works collaboratively with Professors John Griffin and Charlie Monroe working to enhance the production of metals in American manufacturing. She enjoys doing research on practical engineering problems.

-

Recent Courses

- MSE 280 - Engineering Materials

- MSE 350 - Introduction to Materials

- MSE 465 - Characterization of Materials

- MSE 690/790 - Graduate Characterization of Materials

-

Select Publications

- J.A. Griffin, H. Littleton, R.D. Foley, "Effect of Vacuum Assisted Filling and Solidification Under Pressure of A356, A206, Modified 319, and 535 Aluminum Alloys on Tensile Properties Using the Lost Foam Process", AFS Transactions, 122, No. 14-071, (2014), pp. 356-365.

- R. Aristizabal, K. Hayrynen, R.D. Foley, J.A. Griffin, C. Monroe, "Austemperability of Intercritically Austempered Ductile Iron (IADI)", AFS Transactions, 122, No. 14-070, (2014), pp. 279-286.

- D. David, R.D. Foley, J.A. Griffin, C. Monroe, "Microstructural Characterization And Thermodynamic Simulation Of Cast Al-Zn-Mg-Cu Alloys"; AFS Transactions, 122, No. 14-069, (2014), pp.105-116.

- M.D. David, R.D. Foley, J.A. Griffin, C.A. Monroe, "Microstructural Characterization and Thermodynamic Simulation of Cast Al-Zn-Mg-Cu Alloys", International Cast Metal Journal, 10.1, (2016), pp. 2-20.

- M. Laseer, A. Chatterjee, B. Brott, R.D. Foley, O. Alli, M. Sasse, M. Ahmed, F. Al Soliman, G. Reddy, S. Ather "Safety of Hydrophilic Guidewires Used for Side-Branch Protection During Stenting of Bifurcation Lesions" Cardiovascular Revascularization Medicine,In Press.

-

Academic Distinctions & Professional Memberships

- AFS

System Integration

Research activities: Doug Ross

General topics: system integration, robotics, image processing, machine design, actuators

Dr. Ross' area of expertise is in automated systems integration at both the low level of sensors, actuators and controllers and at the high level of robots and CNC machines. Graduate students projects involve creating sub-systems related to automation including mechanical, electrical, and software design.

An example of specific research activities currently in progress:

An example of specific research activities currently in progress:

DIGINOL: A JOULE-HEATED BINARY-PARTITIONED NITINOL ACTUATOR

Control of Nitinol as an actuator is difficult due to the hysteresis in the displacement when heating and cooling. By activating partitions of the Nitinol wire fully as when transistors are used as switches a more robust control can be accomplished.

The electrical connections for the partitions require an optimization of thermal and mechanical properties to best perform its function.

Preliminary project definitions:

- Robotic sorting of plastic containers from other recyclable materials

- Robotic sorting of plastic containers by type

Contact

For more information, please reach out to Doug Ross at

Barber Laboratory for Advanced Safety Engineering and Research (BLASER)

Our BLASER research includes dynamic evaluation of real-life impact events using explicit finite element analysis and physical testing. The focus of this group is crash energy management and enhancing crashworthiness on applications in automotive and sports safety. Current research includes evaluation and design of advanced energy absorbing techniques in football helmets, energy absorbing hockey boards, and development of roadside safety devices including guardrail end terminals, crash cushions, and concrete bridge rails.

Examples of current research:

- Development of Roadside Safety Devices

- Energy Absorbing Hockey Boards

Energy Systems

Current Projects

Solar assisted heat pump system with seasonal storage: Integration of water-source heat pumps with solar thermal collectors is being studied under several input conditions to determine the control strategies that optimize air conditioning of a building with highest coefficient of performance and the least use of auxiliary heating.

Ground source heat pump: Effective operation of ground source heat pumps is dependent on various parameters, selection of which requires a database of operation points under various conditions. A graduate student is working on generating the required data to create the database and develop a decision-making tool for building designers and building managers.

Energy use index study of UAB campus buildings: In a campus environment such a UAB, which is consisted of more than 150 buildings, it is very important to have an accurate measure of energy performance of each building and compare with the data from Building Performance Database that contains data at national level. This will provide info to building managers regarding the status of their building as compared to national average for the given type of building use.

Feasibility study of distributed generation system for UAB buildings: Through energy modeling of several types of buildings, a graduate student is investigating techno economic feasibility of locally generating electricity and other resources such as (cooling, heating and hot water) instead of obtaining them through network.

Internal combustion engine based tri generation of heating, cooling and power (CHCP): Tri generation is a topic that is becoming attractive to real-estate developers, especially for multi-family buildings. The overall fuel efficiency factor can reach a value above 90%.

Concentrated PV thermal management: In concentrated PV applications, power generation can be multiplied however, PV cells get hot very quickly, which results in a significant drop in their efficiency. Different methods for cooling PV cells are under investigation.

Experiments

Additional Resources

- Two SCXI chassis backbones for connection of signals to the Data Acquisition (DAQ) card.

- Three screw terminal boards for use in conjunction with the SCXI chassis

- Two BNC type terminal boards for direct signal connection to the DAQ system

- One 4-channel USB DAQ system.

- An SC-2345 signal-conditioning connector block for connecting signals to the DAQ system

- Stroboscope

- A non-contact temperature measurement device

- A number of pressure transducers in various pressure ranges

- An electrical current transducer

Currently, two of the experiments are equipped with data acquisition systems, so students are able to use LabVIEW modules to collect data from the experiments. Those experiments are: (1) the lift coefficient determination on airfoils in the subsonic wind tunnel, and (2) the cooling tower experiment. In the former, pressure measurements at 15 points, and in the latter, temperature measurements using thermocouples at 7 points, are recorded electronically using the DAQ system. There are two desktop computers equipped with data acquisition cards, and a PCMCIA data acquisition card is available to be used in laptop computers as a mobile data acquisition system. The software programs that are frequently used by students to perform the calculations are EES and MATLAB.

National Competitions

Solar Decathlon 2017: A team of UAB students led by me designed, constructed and tested a net-zero energy solar-powered house. The team shipped the house to the Solar Decathlon Competition in Denver in October 2017. In Denver, the house competed with 11 houses from other universities for energy production, architecture, water conservation, home life, and 6 more contests. Officials from the Department of Energy monitored the comfort parameters of the house closely for 15 days. UAB house ranked 5th overall, while ranking 3rd in two contests. In terms of energy generation, the house ranked #1. Learn more about the competition rankings.

Solar Decathlon 2017: A team of UAB students led by me designed, constructed and tested a net-zero energy solar-powered house. The team shipped the house to the Solar Decathlon Competition in Denver in October 2017. In Denver, the house competed with 11 houses from other universities for energy production, architecture, water conservation, home life, and 6 more contests. Officials from the Department of Energy monitored the comfort parameters of the house closely for 15 days. UAB house ranked 5th overall, while ranking 3rd in two contests. In terms of energy generation, the house ranked #1. Learn more about the competition rankings.

Shell Ecomarathon 2013-2017: Shell ecomarathon is a competition among academic institutions to design, build and race their super-mileage small cars in several different categories. Dr. Taherian has mentored teams of UAB students in this competition since 2013. As of 2017, the team works under the umbrella of Blazer Motorsports.

Contact

For more information, please reach out to Hessam Taherian at

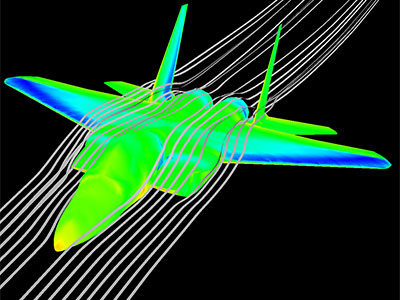

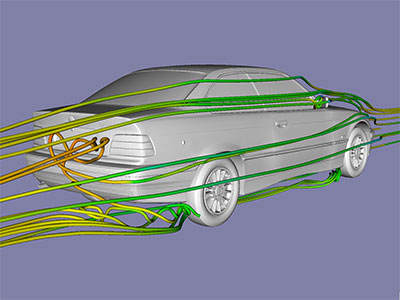

Computational Fluid Dynamics

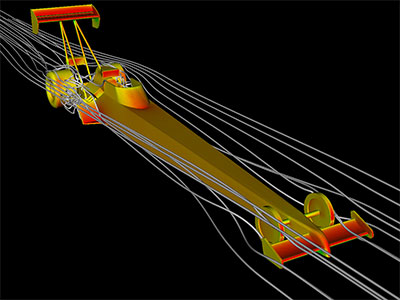

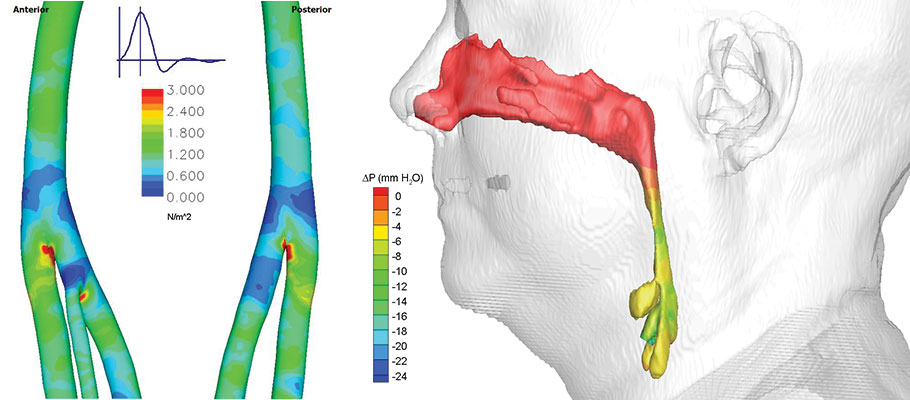

Our research efforts in Computational Fluid Dynamics (CFD) include high performance computing for compressible and incompressible flows, development of finite volume schemes for hybrid and generalized meshes, biomedical flow modeling, unsteady flow simulations, rigid body dynamics simulations with six degrees of freedom (6 DOF), investigation of turbulence models for generalized meshes, application of generalized overset mesh technology, and simulation of pollutant transport through urban areas. Traditionally, computational fluid dynamics techniques are developed for aerodynamics applications. Our research focuses on the application of CFD techniques to traditional, non-traditional, and multi-disciplinary applications.

Researchers in the CFD area work in collaboration with the renowned medical school at UAB to apply CFD techniques for biomedical flow simulations. The complex physiological geometry of the femoral artery bifurcation and the upper airways of sleep apnea patients were created from a sequence of CT - scan images. Blood flow waveforms, derived from Phase Contrast MR Images, were used to generate Womersley velocity profiles that were used as boundary conditions. Equations governing blood flow were solved using a second order time accurate in-house finite volume CFD solver.

The application of CFD techniques to analyze blood flow through femoral arteries and airflow though upper airways of a sleep apnea patient before and after surgery.

The application of CFD techniques to analyze blood flow through femoral arteries and airflow though upper airways of a sleep apnea patient before and after surgery.

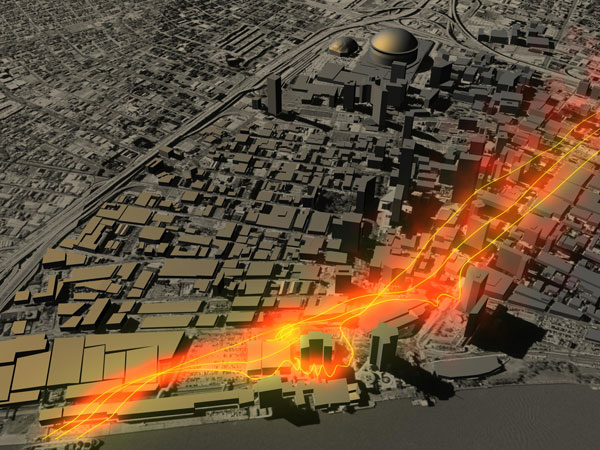

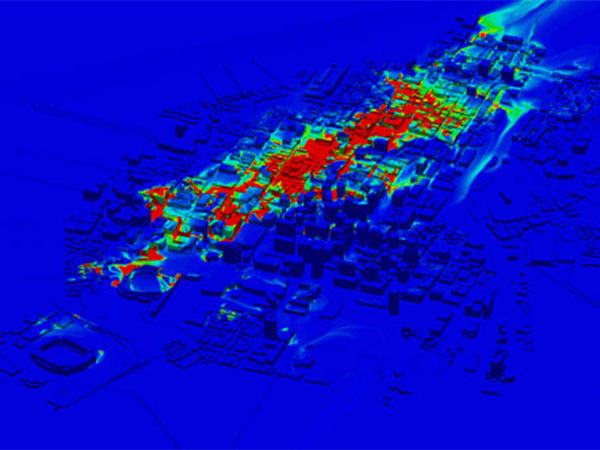

A real-time prediction of the path of the pollutant transport through an urban area, in the case of an emergency, is an invaluable tool for emergency management and planning. However, the real-time simulation of chemical, biological, and radioactive (CBR) agent transport in an urban environment is a formidable task. This requires the modeling of complex city structures, which governs the wind field and in turn governs the path of the pollutant. Information about city structures is available in terms of GIS data which is collected either by a satellite or by an aircraft. Extracting the geometry of the city from this large data set for simulation is a daunting task. Modeling the wind field in the city and consequently the modeling of the transport of the pollutant involve the selection of appropriate governing equations and numerical schemes, and high-performance computing. Also, the visualization of the large number of data sets and feature detection plays a vital role in extracting information that is created by the numerical simulation and conveying this information to officials for decision making.

Many of the Computational Field Simulation (CFS) problems of interest such as store separation, control surface deflections, stage separation, etc. involve objects in the computational domain that move relative to one another. This class of problems presents a challenge for a CFD solver in terms of resolving complex flow features, handling a large relative motion of bodies, and accurately moving the grids associated with moving bodies. Overset meshes are suitable for this class of applications with focus of the research being overset technology for generalized meshes.

Contact

For more information, please reach out to Roy Koomullil at