GAANN program core faculty and key faculty personnel

Chair and Professor, Department of Mechanical and Materials Engineering

Associate Professor, Materials Engineering

Associate Professor and Graduate Program Director, Mechanical Engineering

Associate Professor, Electrical and Computer Engineering

Professor and Graduate Program Director, Civil Construction, and Environmental Engineering

Key Senior Personnel

Professor, Materials Engineering and Director, Materials Processing and Applications Development Center

Associate Professor, Materials Engineering

Assistant Professor, Electrical and Computer Engineering

Assistant Professor, Civil, Construction, and Environmental Engineering

This MSEC GAANN program is to offer fellowships to graduate students with excellent records who demonstrate financial needs to obtain doctoral degrees in 4 identified fields of national needs. We will integrate our demonstrated strengths in materials processing, property testing, structure sensing, simulation, and artificial intelligence to train future PhD students under a new paradigm, in which ultra-durable materials and structures are realized through AI-guided design, simulation, and evaluation for applications under extreme conditions. The resultant systems will address expansive, pervasive, and persistent problems in wide-ranging applications including space exploration, nuclear energy, built environments, etc. The project involves 5 core faculty members plus 4 other key personnel from 3 dynamically growing departments.

University of Alabama at Birmingham

Arizona State University

Rice University

University of California at Davis

Penn State University

Northwestern University

Matt Dickerson, Lisa Rueschhoff, Tim Pruyn (not pictured)

Air Force Research Lab

Naval Research Lab

Lawrence Livermore National Lab

Oak Ridge National Lab

The DoD MURI project includes six main thrusts, with each one requiring significant expertise in a variety of areas. Click on each section below to expand and learn more about each key thrust.

-

Thrust 1: Design and Create

Thrust 1 will design and create new families of single-source precursors.

-

Thrust 2: Ceramization

Thrust 2 will systematically and quantitatively study a wide range of ceramization conditions and approaches.

-

Thrust 3: Atomic Scale Evolution and Transformation

Thrust 3 will characterize atomic scale evolution and transformation and provide fundamental understanding of CCCs.

-

Thrust 4: ReaxFF Simulation

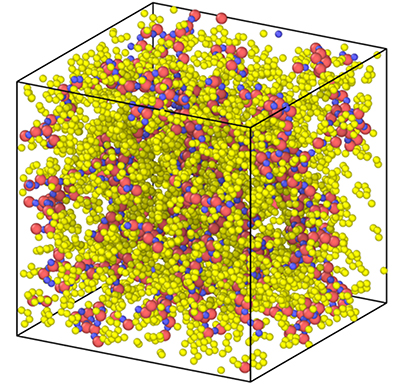

Thrust 4 will advance ReaxFF simulation approaches to provide detailed knowledge of CCCs.

-

Thrust 5: High-Temperature Hypersonics

Thrust 5 will mimic high temperature hypersonic conditions for thermomechanical property and oxidation resistance.

-

Thrust 6: Adaptive ML for Intelligent Design

Thrust 6 will explore adaptive ML for intelligent design and prediction of CCCs.

Multidisciplinary University Initiative (MURI) efforts involve teams of researchers investigating high priority topics and opportunities that intersect more than one traditional technical discipline. For many military problems this multidisciplinary approach serves to stimulate innovations, accelerate research progress and expedite transition of results into naval and aerospace applications.

(from https://www.onr.navy.mil/education-outreach/sponsored-research/university-research-initiatives/muri)

This MURI program aims to understand, design, pyrolyze, and optimize compositionally complex ceramics for hypersonics through an experiment – characterization – simulation – machine learning integrated approach. Our team encompasses world-leading experts in precursor synthesis, pyrolysis study, characterization, reactive force field (ReaxFF) simulation, thermomechanical and thermochemical property assessment, and AI/machine learning. This carefully integrated MURI effort will fill the scientific gap in polymer-to-ceramic conversion and lead to quantitatively designed compositionally complex ceramics of 1400-3000°C.-

Polymer-Derived Ceramics

Polymer-Derived Ceramics

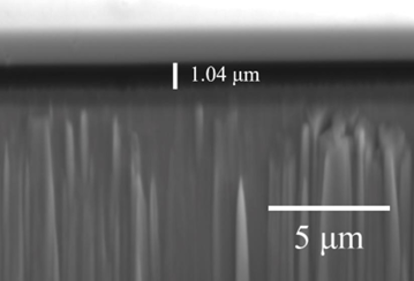

Polymer-derived ceramics have a wide array of promising properties such as high temperature stability, semiconductivity, and controllable microstructure and crystallization that can be finely tuned by altering the chemical composition of the starting polymer and the processing temperature and atmosphere. Current research is focusing on using silicon oxycarbide (SiOC) in environmentally stable and electrically conductive coatings, producing micro- and mesoporous SiOC ceramics with high specific surface areas, and introducing metal organics into the preceramic polymers to produce SiOC with magnetic and electrically conductive properties. We are also studying novel composite synthesis and preparing for flight experiments to the International Space Station.

-

Nuclear Materials

Nuclear Materials

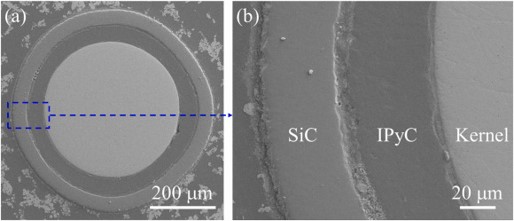

Nuclear fuel design for improved irradiation resistance, easy processibility, stress tolerance, and thermal management, lab testing and ion irradiation to understand the fuel particle and bulk evolution behaviors under the simulated harsh nuclear environments, and comprehensive characterization of atomic to macroscopic structures. This will enable novel nuclear fuel encapsulants, improve fuel damage tolerance, understand self-stabilizing behavior under irradiation, and predict this new material system behaviors for nuclear fuel advancement.

-

New Coatings for Stainless Steel

New Coatings for Stainless Steel

Our interest is to develop novel coatings for nuclear fuel waste canisters in order to address nuclear waste container corrosion and failure problems, identify new and effective mitigation strategies, and safeguard nuclear waste storage, transport, and disposal, in both terrestrial and marine environments. Specifically, we develop effective corrosion-resistant polymer-derived ceramic coatings on 304/304L/304H canisters for improved resistance to pitting in chemically aggressive, chronically stressed, and highly corrosive nuclear environments; evaluate coating structural changes under different nuclear waste storage conditions and test their corrosion responses under aggressive and long-term brine conditions; and advance fundamental understanding of the coating failure mechanisms under combined stress and corrosion conditions as well as identify coating failure repair strategies, especially when exposed to pitting and stress corrosion cracking environments.

Contact:

For more information, please contact Kathy Lu at

The Department of Mechanical and Materials Engineering efforts in Drug Delivery include efforts focused on the diseases of asthma, cancer, COPD, cystic fibrosis as well as infectious disease. We work on small molecule, protein, and oligonucleotide therapeutics with delivery strategies including inhalable aerosols, polymer-based systems, and serum proteins. We work closely with teams at the UAB Heersink School of Medicine, the UAB Cystic Fibrosis Research Center, and Southern Research to help provide better treatments for patients.

For recent publications click here or here.

Polymer nanoparticles and nanogels are developed for theranostic applications. We work on incorporating drug, RNAs, and iron oxide or metal nano-clusters for delivery and imaging along with polymer nanoparticles.

Chronic, inflammatory disease of conducting airways affects 300 million people worldwide. Affluent societies have occurrence in 1 in 10 children and 1 in 12 adults. Estimated economic impact is estimated to exceed $18B. A mixture of genetic susceptibility and environmental risk factors lead to a variety of endotypes and consideration of asthma as a syndrome. Inhalable treatments such as Advair Diskus® contain a cortical steroid to produce anti-inflammatory and vasoconstriction effects, a beta-agonist to relax bronchial muscles, and a lactose excipient to assist in formulating micron-sized particles for optimal delivery into the lung.

Chronic, inflammatory disease of conducting airways affects 300 million people worldwide. Affluent societies have occurrence in 1 in 10 children and 1 in 12 adults. Estimated economic impact is estimated to exceed $18B. A mixture of genetic susceptibility and environmental risk factors lead to a variety of endotypes and consideration of asthma as a syndrome. Inhalable treatments such as Advair Diskus® contain a cortical steroid to produce anti-inflammatory and vasoconstriction effects, a beta-agonist to relax bronchial muscles, and a lactose excipient to assist in formulating micron-sized particles for optimal delivery into the lung.

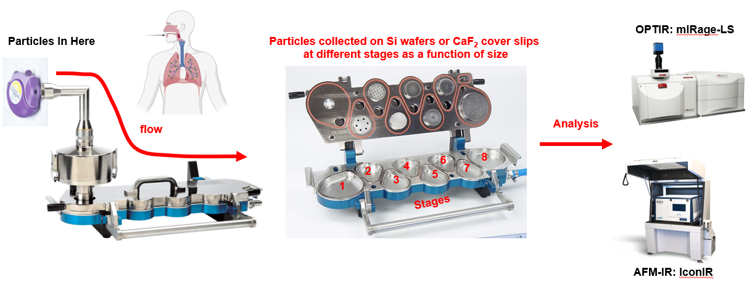

At UAB MME, the Spectroscopic Histology Service Center features the mIRage-LS O-PTIR and IconR AFM-IR for characterization of the aerosol particles as a function of aerodynamic size. We use the capabilities to optimize the co-localization of drug on the aerosol particles, which is known to impact efficacy in a synergistic fashion, and to develop bioequivalence methods for comparison of Name Brand and Generic drug formulations. For design we optimization of aerosol drug formulations, the lab features a spray dryer and Next Generation Impactor.

At UAB MME, the Spectroscopic Histology Service Center features the mIRage-LS O-PTIR and IconR AFM-IR for characterization of the aerosol particles as a function of aerodynamic size. We use the capabilities to optimize the co-localization of drug on the aerosol particles, which is known to impact efficacy in a synergistic fashion, and to develop bioequivalence methods for comparison of Name Brand and Generic drug formulations. For design we optimization of aerosol drug formulations, the lab features a spray dryer and Next Generation Impactor.

Contact

For more information, please reach out to:

Mark Banaszak Holl at

Vinoy Thomas at