University of Alabama at Birmingham researcher Eugenia Kharlampieva, Ph.D., makes polymer microcapsules meant to carry cancer drugs to the site of a tumor. Working in the UAB Department of Chemistry at the intersection of polymer chemistry, nanotechnology and biomedical science, she is creating novel “smart” particles that will provide controlled delivery for therapeutic drugs. Specifically, she has found that changes in shapes or elasticity of these tiny carriers greatly influence their ability to surmount the drug-delivery hurdles that lie between an injection into a vein and engulfment into a cancer cell.

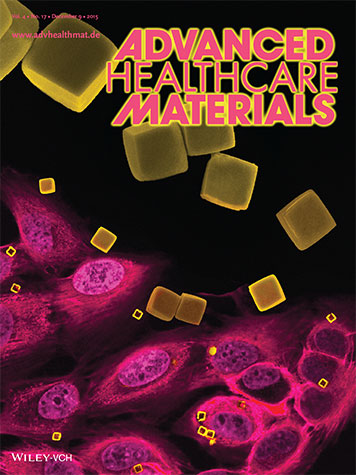

Alexander, JF; Kozlovskaya, V; Chen, J; Kuncewicz, T; Kharlampieva, E; and Godin, B; Cubical Shape Enhances the Interaction of Layer-by-Layer Polymeric Particles with Breast Cancer Cells. Advanced Healthcare Materials, 2015, Vol. 17, front cover. Copyright Wiley-VCH Verlag GmbH & Co. KGaA. Reproduced with permission.

Alexander, JF; Kozlovskaya, V; Chen, J; Kuncewicz, T; Kharlampieva, E; and Godin, B; Cubical Shape Enhances the Interaction of Layer-by-Layer Polymeric Particles with Breast Cancer Cells. Advanced Healthcare Materials, 2015, Vol. 17, front cover. Copyright Wiley-VCH Verlag GmbH & Co. KGaA. Reproduced with permission.

In a recent paper, Kharlampieva and colleagues compared four different microcapsules — rigid cubes or spheres, and elastic cubes or spheres — to see how they perform against three challenges. The first is avoiding engulfment by healthy macrophage immune system cells that act as lookouts and first defenders against foreign pathogens entering the body. The second is the ability to squeeze through the tiny openings in the walls of unhealthy blood vessels to reach tumor cells. The third is getting taken up by tumor cells, where they can deliver their chemotherapy payload.

In the in vitro experiments, the team found clear winners. For the macrophage challenge, the elastic spheres and cubes were far better at avoiding engulfment compared with the solid spheres and cubes. This potentially means less harm to the healthy immune system cells and a longer half-life in the bloodstream for the elastic therapeutic microcapsules.

“We want them to stay away from macrophages, which are like the clearing soldiers of the bloodstream,” Kharlampieva said. “We found that the hollow particles are much more elastic, and they are not taken up by macrophages, which is fantastic.”

In the challenge of squeezing through tiny openings, the elastic spheres and cubes again were far better than the solid microcapsules. The walls of the microscopic blood vessels in tumors have openings that range between 300 nanometers to 1.2 micrometers. The researchers found that the elastic microcapsules, which are 2 micrometers wide, could squeeze through pores that were two to three times smaller than the diameters of the particles. And after squeezing through, the microcapsules regained their shapes as spheres or cubes.

In tests of uptake into breast cancer cells, the cubes — whether solid or elastic — showed greater uptake, possibly because the flat walls have greater surface area contact with the cells.

Thus, overall, the researchers write, “Our data show that elastic cubical capsules possess important biological characteristics, which can warrant their further development for cancer therapy.”

The next step for Kharlampieva and her colleagues will be testing the biological significance, looking at how changes in shapes and elasticity affect the fates and destinations of these polymer microcapsules in the bloodstreams of mice.

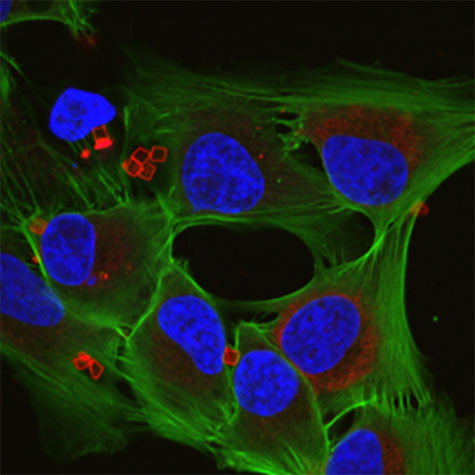

Laser scanning confocal microscopy image of SUM159 human breast cancer cells incubated with cubic capsules for 24 hours. Cell nuclei are stained blue, cell skeleton is stained green, and the capsules are labeled with a red fluorophore. Credit: E. KharlampievaDetails

Laser scanning confocal microscopy image of SUM159 human breast cancer cells incubated with cubic capsules for 24 hours. Cell nuclei are stained blue, cell skeleton is stained green, and the capsules are labeled with a red fluorophore. Credit: E. KharlampievaDetails

To manufacture the spheres and cubes, Kharlampieva and colleagues start with solid scaffolds — either a spherical particle of silicon dioxide or a cubic crystal of manganese carbonate. They then coat the particles with five bilayers of polymers, using tannic acid and poly(N-vinylpyrrolidone). For the solid microcapsules, they leave the scaffolds in place. For the elastic microcapsules, they remove the scaffolds with either acid or a chelating agent.

The resulting microcapsules are water-soluble, nontoxic and biodegradable, which suits them for the job of controlled drug delivery, and the polymer walls of these shapes are just 50 nanometers thick. Their elasticity is measured with an atomic force microscope, and they are so small that a line of 12,700 of the microcapsules would measure 1 inch.

Kharlampieva’s investigation of the effects of shape and elasticity comes from the simple observation that cells of the body that travel through the bloodstream are not spherical and are quite elastic.

The paper, “Cubical shape enhances the interaction of layer-by-layer polymeric particles with breast cancer cells,” was published in Advanced Healthcare Materials, and the cover art features the research. UAB authors of the study are Kharlampieva, Veronika Kozlovskaya, Ph.D., and Jun Chen, all of the Department of Chemistry. Authors at the Houston Methodist Research Institute are Jenolyn Alexander, Thomas Kuncewicz and Biana Godin, Ph.D. Kharlampieva and Godin are the corresponding authors. Alexander and Kozlovskaya are co-first authors.

Financial support came from NIH U54CA143837, NIH 1U54CA151668-01 and NSFCAREER1350370.