Media contact: Katherine Shonesy, kshonesy@uab.edu

Near the edge of campus, a group of UAB engineers is designing and building the ultimate refrigerator.

But these appliances don’t come with ice makers, and you won’t find them for sale in Lowe’s or Home Depot. Instead, the fridges, created by the Engineering and Innovative Technology Development (EITD) team in the UAB School of Engineering, are headed for a loftier home aboard the International Space Station (ISS).

An astronaut aboard the International Space Station opens one of the UAB freezers. Photo courtesy of NASA.NASA uses freezers developed by EITD to protect vital scientific experiments. Astronauts “can transport everything up to the station, do their science, and store samples until they bring them back to the ground for analysis—all while keeping them frozen or refrigerated at the required temperature,” says Dan Connor, EITD’s flight systems specialist. The latest model, named Polar, is half the size of a dorm-room mini fridge and capable of reaching -80°C (-112°F), a temperature that can essentially freeze particle movement in the scientific samples. Those might include cell cultures or experiments involving blood or urine.

An astronaut aboard the International Space Station opens one of the UAB freezers. Photo courtesy of NASA.NASA uses freezers developed by EITD to protect vital scientific experiments. Astronauts “can transport everything up to the station, do their science, and store samples until they bring them back to the ground for analysis—all while keeping them frozen or refrigerated at the required temperature,” says Dan Connor, EITD’s flight systems specialist. The latest model, named Polar, is half the size of a dorm-room mini fridge and capable of reaching -80°C (-112°F), a temperature that can essentially freeze particle movement in the scientific samples. Those might include cell cultures or experiments involving blood or urine.

EITD traces its origins to 1990, when UAB engineers conducted a trial to grow protein crystals in space, explains director Lee Moradi, Ph.D., associate professor of engineering. Since then, the group has forged a healthy working relationship with NASA as part of its Cold Stowage team, with projects flying aboard more than 90 space missions. The ISS currently carries multiple Polar units and other EITD freezers.

Attention to detail

Designing fridges for space travel presents some novel obstacles, says Rob Rouleau, EITD’s associate director. For example, the equipment “has to handle the pressure loads, temperature changes, and vibration loads of launching,” he says. Then the devices must meet NASA’s rigorous requirements, which have life-or-death implications in orbit. Even a simple water line has the potential to imperil a mission if the pressure level is off. “Fluids act differently in space,” Rouleau notes. “We don’t want an astronaut to hook up a water line and cause an explosion of water everywhere.”

The attention to detail starts with assembly in EITD’s campus workshop. Total traceability is a must in the event that anything goes wrong with the equipment or any manufacturers issue a hardware recall, says Rouleau, who asserts that he can identify “where and when a screw was made.” Safety-critical parts on the freezers must be replaced after every flight, making the worn nuts and bolts handy mementos for visitors. “I don’t want to throw something away that’s been to space,” he adds.

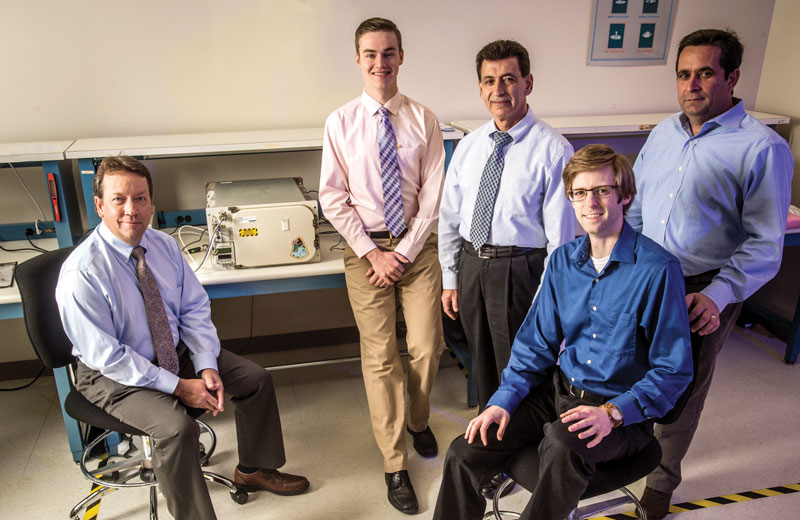

A Polar unit sits with some of the team members who keep it running smoothly, including (left to right) Rob Rouleau, Joe Moore, Lee Moradi, Brandon Kirkland and Dan Connor. Once they’re assembled, the freezers undergo extensive testing to ensure quality control and adherence to NASA’s standards. One of the biggest challenges, says UAB doctoral student and EITD mechanical engineer Brandon Kirkland, is keeping the fridges as quiet as possible.

A Polar unit sits with some of the team members who keep it running smoothly, including (left to right) Rob Rouleau, Joe Moore, Lee Moradi, Brandon Kirkland and Dan Connor. Once they’re assembled, the freezers undergo extensive testing to ensure quality control and adherence to NASA’s standards. One of the biggest challenges, says UAB doctoral student and EITD mechanical engineer Brandon Kirkland, is keeping the fridges as quiet as possible.

For astronauts living on the ISS for months at a time, the never-ending hum of machinery presents a unique danger. “I’ve been told that if the noise is loud and constant enough, they could lose some hearing,” Kirkland says.

In EITD’s “clean room,” Kirkland and others run tests on the Polar units in a large walk-in container known as an anechoic chamber, where reflected sound is neutralized and the freezers’ cryocoolers can be tweaked to make as little noise as possible. Though the fridges already meet NASA’s sound requirements, the team’s goal is to surpass them, Kirkland says, because “the quieter we can make these units, the more we can send to the station.”

After testing the fridges, the engineers load them into a van for the long drive to Florida’s Kennedy Space Center. “The excitement has never diminished,” Rouleau adds. “We take a lot of pride when we’re shipping the equipment. Everybody rubs it to give it some luck.”

Mini mission control

EITD’s work doesn’t end once its freezers are rocketing toward the ISS. The team also is tasked with monitoring them while deployed and maintaining them when they’re not. “This is facility support,” Connor notes.

Patches commemorate past missions that took Polar, along with Merlin and Glacier, two other EITD-made freezers, to the ISS.Connor grew up with the space program. His father worked on the Apollo missions in Huntsville. “I would meet astronauts—moon guys—when they would come back,” he recalls. “That drove me into this career.” Now he’s an engineer, but also something of a mechanic, though his machines usually are far out of reach.

Patches commemorate past missions that took Polar, along with Merlin and Glacier, two other EITD-made freezers, to the ISS.Connor grew up with the space program. His father worked on the Apollo missions in Huntsville. “I would meet astronauts—moon guys—when they would come back,” he recalls. “That drove me into this career.” Now he’s an engineer, but also something of a mechanic, though his machines usually are far out of reach.

To help bridge that distance, Connor and EITD set up the Remote Operations Control Center (ROCC), a low-lit room of monitors displaying real-time statistics from equipment in orbit along with live video feeds from the ISS. From campus, the engineers can observe the freezers and address any problems via audio, video, and data connections to the station. Previously, UAB engineers “would sit in Mission Control for two weeks,” Connor recalls. Now the team has even put ROCC in their pockets, developing apps to check on the space fridges via smartphone. “If something goes out of limits, I get a text alert, so I know what happens [on the station] before Ground Control recognizes anything,” Connor says.

DIY design

The EITD team includes several UAB engineering students with an ambition to solve problems in novel, sometimes abstract ways and an Internet-savvy, do-it-yourself ethos. Kirkland, for example, set up a lab for producing cryocooler prototypes, complete with a 3-D printer that he built for such a low cost that EITD was able to get a second one. “We can do our own thing here instead of sending it to Marshall [Space Flight Center in Huntsville],” Rouleau says.

Another student, junior electrical engineering major Joe Moore, is helping EITD apply its expertise to meet design challenges here on earth. The Atlanta native currently is developing novel devices that could help Birmingham’s Lakeshore Foundation facilitate exercise and fitness for people with disabilities. He also created his own lab within EITD. “I have 24-hour access, so if there’s a problem, I say, ‘Can I build/fix it?’ Usually I can, because I have all these resources,” Moore says. (Discover how Moore is designing the future of fitness.)

UAB's freezers often fly to the ISS aboard SpaceX Dragon capsules. Photo courtesy of NASA.“I love to showcase what these younger folks are doing,” Rouleau says. “They bring a freshness and excitement to the table.” That will come in handy, because EITD has plenty of work on its horizon. The group recently won a five-year contract to help facilitate ISS research through the Center for the Advancement of Science in Space. EITD also is manufacturing new “rapid freeze” units to preserve small samples such as cells or blood in seconds—even milliseconds. Named SMRF and Polar-RF, they are much smaller than their freezer forebears. SMRF is designed as a stand-alone module, while Polar-RF resembles existing Polar units. Using the new prototype lab, the EITD team manufactured demonstration units to present to NASA. Instead of selecting just one RF unit, as Moradi expected, the space agency funded both.

UAB's freezers often fly to the ISS aboard SpaceX Dragon capsules. Photo courtesy of NASA.“I love to showcase what these younger folks are doing,” Rouleau says. “They bring a freshness and excitement to the table.” That will come in handy, because EITD has plenty of work on its horizon. The group recently won a five-year contract to help facilitate ISS research through the Center for the Advancement of Science in Space. EITD also is manufacturing new “rapid freeze” units to preserve small samples such as cells or blood in seconds—even milliseconds. Named SMRF and Polar-RF, they are much smaller than their freezer forebears. SMRF is designed as a stand-alone module, while Polar-RF resembles existing Polar units. Using the new prototype lab, the EITD team manufactured demonstration units to present to NASA. Instead of selecting just one RF unit, as Moradi expected, the space agency funded both.

Moradi sees a through-line connecting UAB’s engineering classrooms to EITD’s growth—and to future opportunities for space commerce and science tied to NASA’s planned missions and the arrival of private companies to spaceflight. “We don’t want to just teach our students theory,” he says. “We are hardware builders. We want to teach them how to build.”