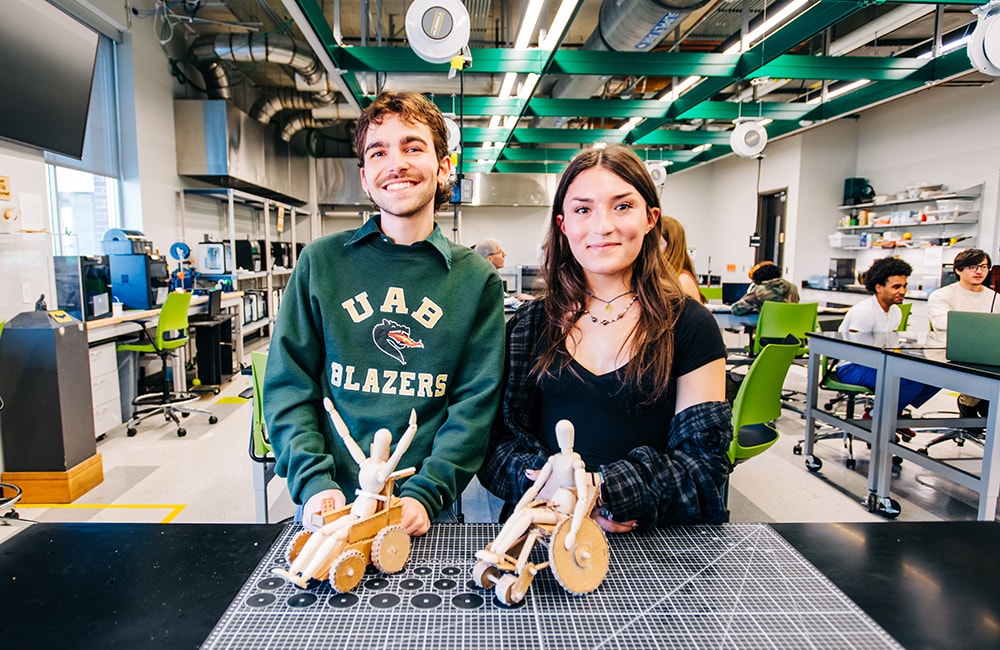

On a recent Friday, undergraduate students crowd into the Design x Prototyping Lab on the main floor of the School of Engineering’s new building, Francis and Miller Gorrie Hall. At one table, a model kidney is being fitted into a 3D-printed rib cage; at another, a student connects circuits with a soldering iron while following a YouTube tutorial. Next to the windows, a laser cutter is etching wood while a group carefully stirs a beaker full of what they hope will be realistic skin. At the periphery, a visiting class of high school students takes it all in.

Most of the undergraduates here now are part of the school’s hands-on Project Lab. They have dropped in for their weekly meet-up and progress check with the lab's director, Timothy Wick, Ph.D.

Wick started Project Lab a decade ago to give undergraduate students an early opportunity to build engineering devices. Students also build up their soft skills in working with clients, which often include state agencies, local nonprofits, and UAB researchers and educators. “We try to find projects that students can complete in one or two semesters,” Wick said. “At the end, they have something to show for their work, and so does the client.”

Although Wick is a professor in the Department of Biomedical Engineering and director of the School of Engineering’s bachelor’s degree in engineering design, “Project Lab is not associated with any department,” Wick said. “It’s an extracurricular way for engineering students to get hands-on design and experience.”

Apply to UAB

There's never been a better time to be a Blazer. Apply today.

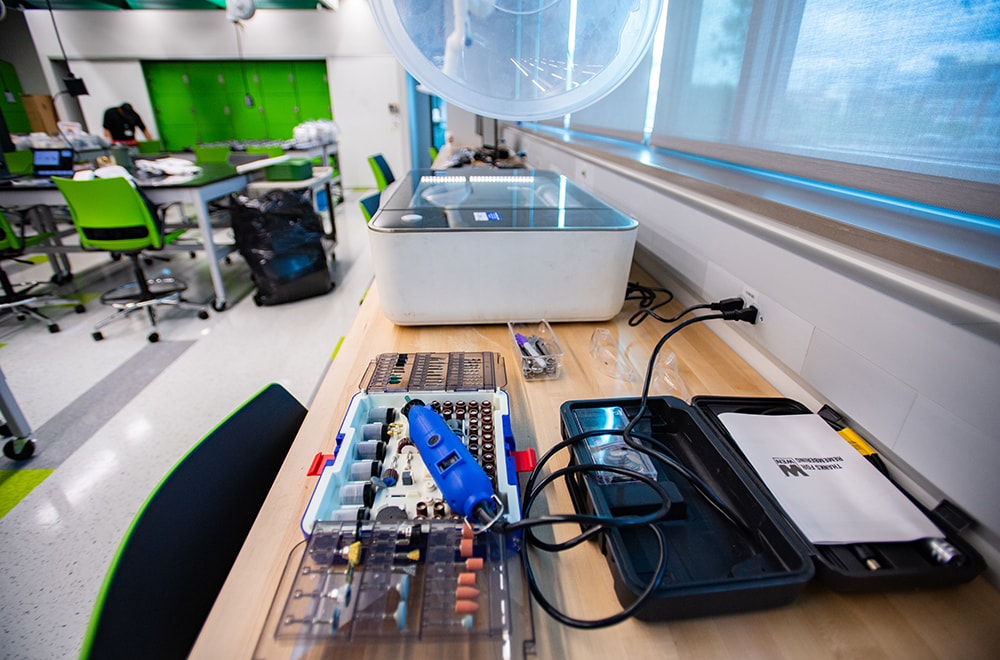

There is a lot to get your hands on in the Design x Prototyping Lab, one of the first spaces that visitors reach when entering Gorrie Hall, which opened in June 2025. The lab has nearly a dozen 3D printers, along with laser cutters, a computer-controlled milling machine and a waterjet cutter that can cut metals of all types. There is also a plentiful supply of cardboard, which is still the best material for early ideation and prototyping, Wick says. (Photo above and photo below by Ian Logue, UAB Marketing and Communications)

Schedule a tour

Want to check out the Design x Prototyping Lab, the rest of the School of Engineering, or all that UAB has to offer. Book a tour here.

“We are definitely one of the highlights on tours for prospective students,” Wick said. “This is the exciting part of being an engineer. You can build something and make the world a better place. We bring in students from high schools around the state, particularly those with engineering academies, to show them what being at UAB is like.”

Take a look around in the images below:

Photo above: Allie Reinhart, a biomedical engineering major, updates her lab notebook for her Design Lab project — a medical simulation trainer for Children’s Hospital. “The specific technique they are doing is pericardiocentesis,” Wick said. The pericardium, he explains, is a sac around the heart that is filled with fluid “to protect the heart from banging on the ribs.”

Photos above: When too much fluid fills the sac, doctors “use an X-ray to stick a needle in the pericardium, which works great if you get the needle in the right place,” Wick said. Reinhart is developing a simulator to allow medical residents to practice the technique. She is working with Nick Rockwell, M.D., assistant professor in the Division of Pediatric Critical Care, associate co-director of Simulation in the division and a 2008 biomedical engineering graduate of the School of Engineering.

Photos above: Brianna Savage, a freshman majoring in biomedical engineering, demonstrates her initial design for a portable ramp for a person with a wheelchair — a project suggested by her clients at the Alabama Department of Rehabilitation Services.

Photos above: Alex Johnson, who is majoring in engineering design, works on his project, a Braille teleprompter, also for the Alabama Department of Rehabilitation Services. “Instead of static Braille, like a book in a library,” this project is working to make a device that can change the text as it is being read,” Wick said.

Photo above: Eva German Garcia (left), majoring in mechanical engineering, and Amelia Hunt (right), majoring in biomedical engineering, work on molds for their project with the Department of Pediatrics to model different stages of breast development. Their client, Assistant Professor Christy Foster, M.D., is using these to help train pediatrics resident trainees in physical examination techniques.

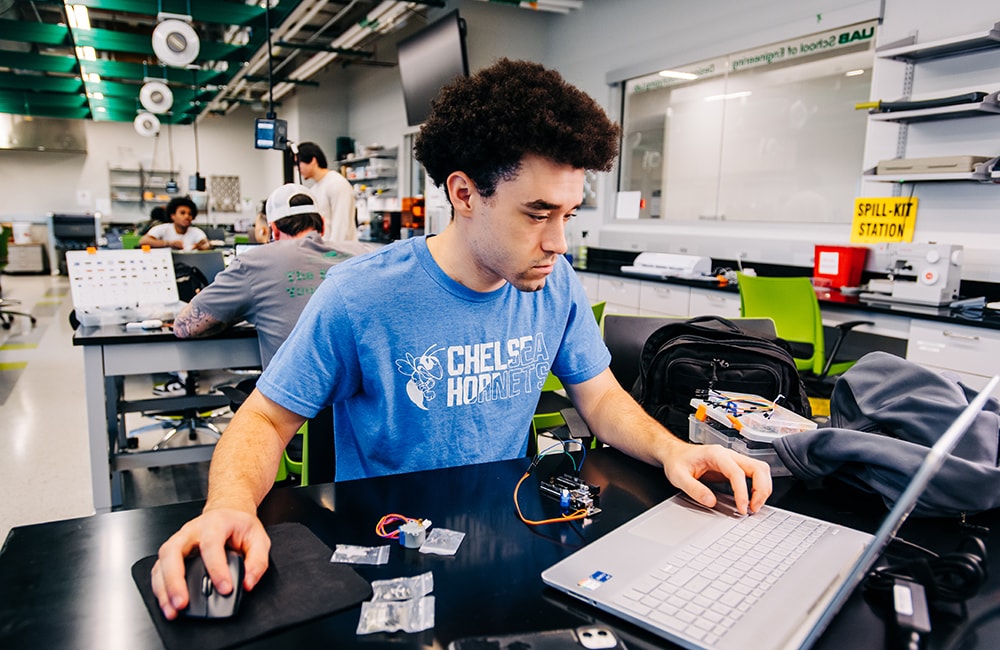

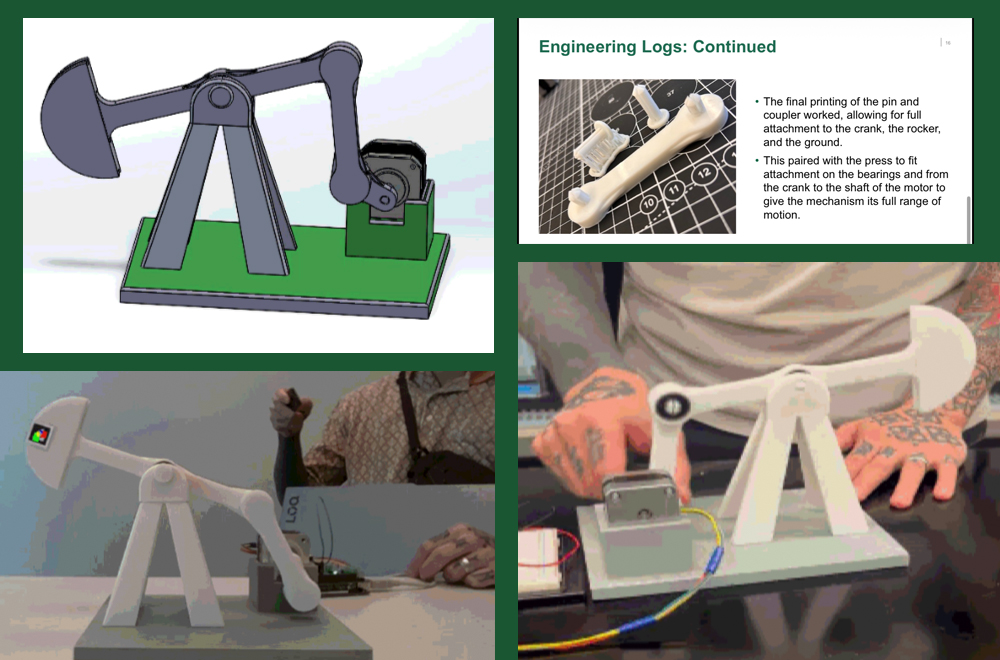

Photo above: Unlike most of the other students in the lab on this day, John Riggins is not part of Project Lab. A senior majoring in mechanical engineering, Riggins is working on a project for ME 370, Kinematics and Dynamics of Machines, taught by Andres Morales, Ph.D., instructor in the Department of Mechanical and Materials Engineering. “The assignment was to design, 3D print and build a four-bar linkage mechanism and do all the associated computer-aided modeling and analysis," Riggins said. (See images from their work in progress below.) He and his group ended up with a working beam pump, which is used in oil fields, “that demonstrated the motion and mechanics we had seen in CAD testing.”

Photo above: Riggins says he was excited by the class and that, after he finished the project early, he “wanted to dive in more to learn some microprocessor controls.” In the photo above, he is wiring an Arduino Uno R3 board, a motor shield and a stepper motor with a remote sensor “so I could control the movement of our project with a remote, instead of the instructor controlling it from his written program,” he said.

Photo above: “The assignment was to design, 3D print and build a four-bar linkage mechanism and do all the associated computer-aided modeling and analysis," Riggins said. (See images from their work in progress above.) He and his group ended up with a working beam pump, which is used in oil fields, “that demonstrated the motion and mechanics we had seen in CAD testing.” Images courtesy John Riggins

Photo above: Cam Boydstun and Mason Hotchkiss (left and right in the photo above), and Tony Tamburello (left in photo below, with Boydstun) are all engineering design majors. Their project is to develop a surgical trainer for client Carmen Tong, D.O., assistant professor in the Department of Urology. The goal is to help surgeons learn how to remove cancerous tumors from kidneys using DaVinci robotic surgery devices. The engineering students are creating a tactile model of the kidney that can give realistic feedback as surgeons learn to manipulate the DaVinci to snip away tumors from delicate kidney tissue.

Photo above: The initial project connection came through Pierce Plumlee, a 2024 graduate in BME/mechanical engineering at UAB. “Pierce is working in Dr. Tong’s lab, and he put her in touch with us,” Wick said. “That is usually what happens; typically, they find me, and then I organize teams of students, make the introduction between the team and the client, and then mentor the team in the background.”