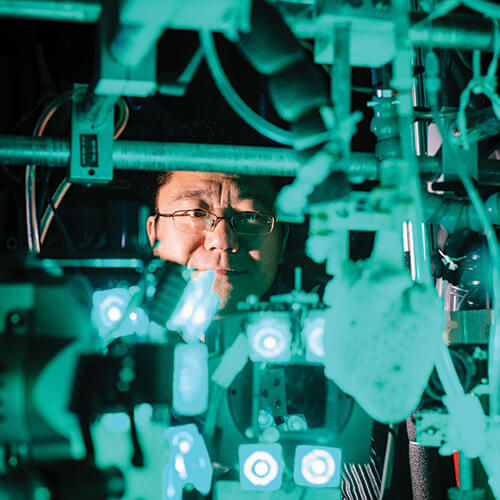

UAB’s School of Engineering is the place to establish your foundation for a career in engineering—or whatever path you choose. Our faculty, research, degree programs and internships will give you the tools you need to succeed. Build your future with us.